It might baffle you but about 80% of a modern aircraft is made from Aluminium. Yes, the same silvery metal which you find on your window frames, bicycles and that foil you wrap your sandwich with. When an aircraft designer embarks on a plan to make a plane, there are a million things which come at play. However, everything else falls into place around three main conditions – a light-weight body, a rust-free durable frame, and high fuel efficiency. A metal that checks all the boxes is Aluminium.

|

| Modern Passenger Aircraft |

Our readers might already know that aluminium was already being used for building aviation vehicles before the Wright brothers used it to make their first manned flight. In the late 19th century, Count Ferdinand von Zeppelin used it to make the frames of his famous Zeppelin airships.

Let’s wind back a bit in history and follow the journey of aviation through the lens of the 'Strategic Metal'.

On December 17, 1903, Orville and Wilbur Wright made the world’s first human flight with their airplane, the Wright Flyer, four miles south of Kitty Hawk, North Carolina. The “heavier than air” aircraft was carefully designed to sustain a flight of 120 feet (37 m) in 12 seconds, at a speed of only 6.8 miles per hour (10.9 km/h) over the ground. They had carefully selected aluminium to cast the engine block and the cylinders combined with the wooden framework, an innovation at that time to maintain the weight as low as possible. Interestingly, the engine had no fuel pump. Gasoline was fed from the fuel tank which was mounted on a wing support into a chamber. It was here that the fuel got mixed with the air, vaporized and then forced into the cylinders to deliver power. The small leap that the plane took into air lit the imagination of millions who saw the historic photograph of a man flying like a bird!

|

| Man's First Flight |

Aluminium was still not much into popular use back then due to the lack of the industrial expertise of manufacturing it on a large scale. It would take over a decade for the use of aluminum to become more widespread.

World War 1 brought in much scope for innovative usage of different metals, pioneered on an industrial scale. Aluminium usage increased in the making of aircraft and aerospace vehicles because of its unmatched weight reducing characteristic by as much as 3 times than iron and steel while offering non-corrosive and “thrice as stronger than steel” proposition at the time. Incidentally, it blew away wood from any further usage in the industry, which was a good thing.

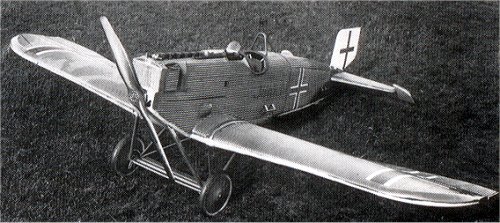

The world’s first full metal aircraft to have lifted itself above the ground was made in 1915 by a German aircraft designer Hugo Junkers. His plane initiated the use of strong alloys consisting of aluminium, copper, manganese, and magnesium. The time was right to get an edge over the other nations through air supremacy in the war. This gave birth to the era of globally superior aviation.

|

| Junker's Aircraft of WW I |

The period between World War I and World War II (1918 - 1939) famously came to be known as the ‘Golden Age of Aviation’. The race between the East and the West to make superior aircraft led to ground-breaking research and manufacturing capabilities on both sides of the ocean. The biplanes were discarded for aerodynamically superior monoplanes which were created from all-metal frames made from aluminium alloys. Various nations like Britain, Germany and the US had formidable bomber planes capable of overturning the fate of battles and eventually the war.

World War II saw soaring demand for aluminium in military applications. It was so great that in 1942, WOR-NYC broadcast a radio show ‘Aluminum for Defense’ to inspire American civilians to contribute scrap aluminium towards the war efforts. Recycling aluminium was encouraged, and “Tinfoil Drives” offered free movie tickets in exchange for aluminum foil balls!

|

| A "Tin foil drive" during World War II |

It is said that at its peak (circa 1944), Americans were making around 11 aircrafts per hour, mostly from aluminium. By the end of the World War, America had the most dominant air force in the world.

Look out for our next article where we fly into modern uses of aluminium in today's aircrafts!

Comments

Post a Comment